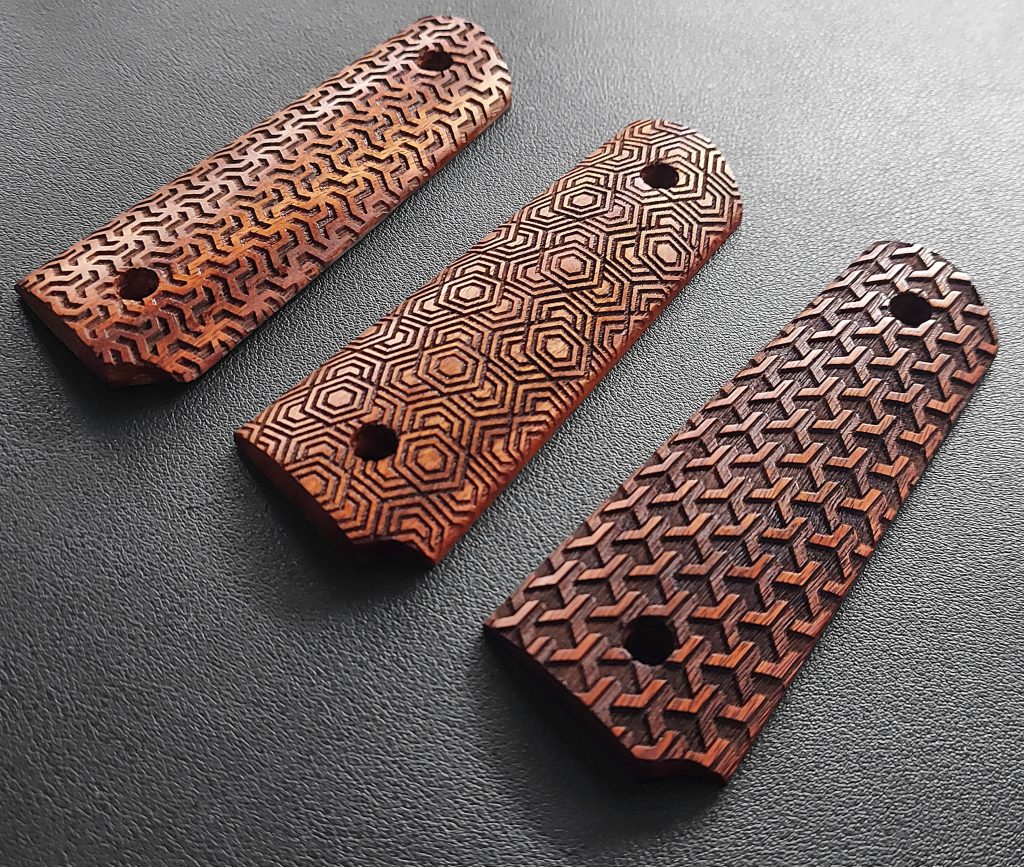

Challenge: Very special grips in Quebracho wood for some luxury 1911 in limited series addressed to key people.

Quebracho Colorado (schinopsis lorentzii), its name comes from Spanish “quiebra-hacha” (axe-breaker), is the second hardest wood of the world, just a bit behind to the Australian Buloke (less than a 2% difference).

To better understand. Quebracho is 3+ times harder than walnut or rosewood and 2+ times harder than ironwood or ebony. Its weight is up to 1,3 metric tons per cubic meter, 30% heavier than water!

Wild Quebracho is a by-law protected tree and since 1959 it cannot be cut. Due to its rarity (it’s the ivory of woods) has a stellar market price, up to 85.000$ per cubic meter.

We are the few having that since we purchased 150 years old benches of the Estudiantes de la Plata stadium in Buenos Aires, left to dry for a 10-year time. Humidity is therefore less than 0.25% (dry Ebony average is between 6% and 9%).

At the beginning, we were quite skeptics regarding the possibility of making a so small part in a so hard wood, but the heavy insistence of our friend to whom we cannot say no, convinced us to try.

The challenge was not easy. From one side to create an appropriate tool to hold the pieces to be machined and from the other one to identify a suitable manufacturing method (CAM) and tooling for a 5-axis CNC center.

Just to technicians. After some tests, we were obliged to use only special designed (for us) diamond cutters because those in integral widia were consumed like butter as the quebracho is highly mineralized.

More, it was necessary to create a cooling system (as for metals) to contain the temperature of the cutter during machining. To avoid fire, instead of air we use nitrogen. Practically, a unique case for wood.

The finishing process necessarily takes place with hand polishing using sandpapers scaling up from 320 until 2500 grit (the one used to gloss paints). With this process Quebracho almost vitrifies.

The compactness of fibers is such that once finished it does not even absorb oil since it has a degree of polymerization (ratio between the molecular weight of the polymer and that of the individual repetitive units that compose it) higher than many of the hard plastics and corresponding to the half of Kevlar…

Its peculiar red color, thanks to the incredible quantity of tannin it contains, is unique and makes it extremely warm and pleasant. In addition, it preserved from weather and sun.

The result we obtained was very exciting, a literal statement from the customizer. So, we decided to make a limited series also for the EU market.

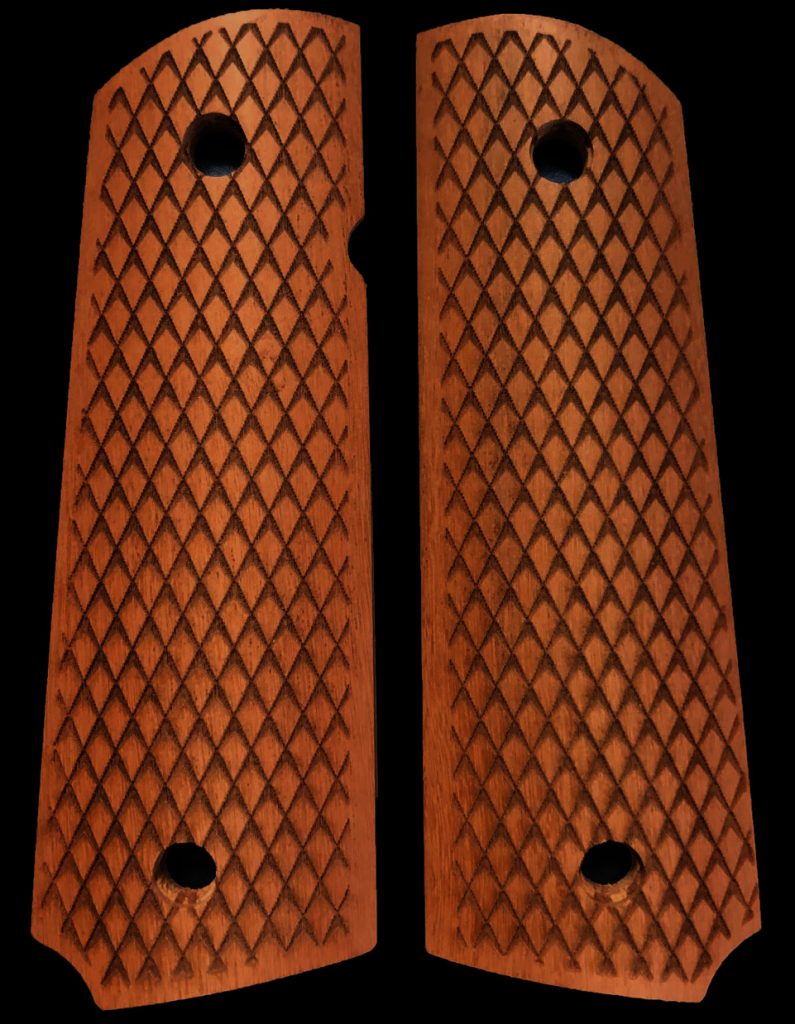

Unfortunately, the cost of the raw material on the one hand and the complex manufacturing on the other one make this extremely luxurious product expensive (if they were made of walnut the grips would cost less than a third). We also made 1911 grips in lapacho (same wood family but less rare and with a brown color) and in top quality walnut natural oil finished.

Our quebracho grips are therefore life guaranteed.

https://www.mtkoutlet.com/en/53-handgun-grips